Tzu-Heng Hsu

Summary

Having 2.5 years of experience in the semiconductor industry, I have learned to be a good team player and analyzed issues comprehensively and thoroughly through discussions. And the most important thing is I like solving problems through teamwork. Besides, the reason that motivated me to apply for the job position was that I would like to reach further and deeper in the semiconductor industry not only from the aspect of manufacturing but also from that of designing and testing.

Work Experience

Research Development Etching Process Engineer

• Taiwan Semiconductor Manufacturing Company (2019/01 - Now)

Devoting to the process improving, yield-enhancing, new equipment function development, relevant testing verification, processing data organization, Process deviant analysis, Preventive mechanism establishment. Also, cooperating with other departments to improve the designation of the manufacturing process.

1. Responsible for special Etching processes yield improvement for 10%.

2. Developing auto Swap wafer functions increases production yield by 12%.

3. Defect analysis and reduction.

4. Teamwork with vendors to do new function testing and data collection.

5. Using Fault Detection & Classification System do the troubleshooting.

6. Tool parameter category and management and also use them as a Preventive mechanism

7. Tool retrofit and software upgrade data validation and function testing.

8. Recipe modification and tool production sequence research

3D Printer Education Associate Intern

CHIGI Studio(2015/09-2016/06)

Devoting to promoting "Maker", everyone can invite everything you want with a 3D printer. Responsible for teaching children how to use 3D printers and how to use online software to draw 3D designs.

- Maintenance of 3D printer.

- Modifying CAD files.

- Guide and introduce 3D Printers in the high school campus.

- Planning Elementary school 3D printing activity.

Education

Master Degree (2016-2018)

National Tsing Hua University

Engineering and System Science department

GPA: 4

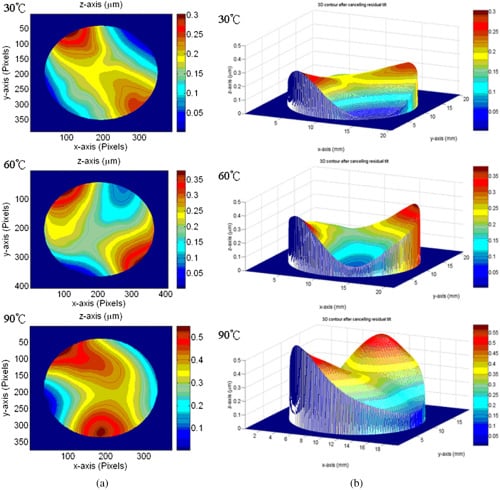

- Dissertation: The study and development of Pulsating Heat Pipe of the solar thermal storage system at different ambient temperatures

- Awarded Chongqing Heat pipe institution "The Best Slide Presentation Award"

Bachelor's Degree (2012-2016)

National Central University

Mechanical Engineering department

GPA: 3.2

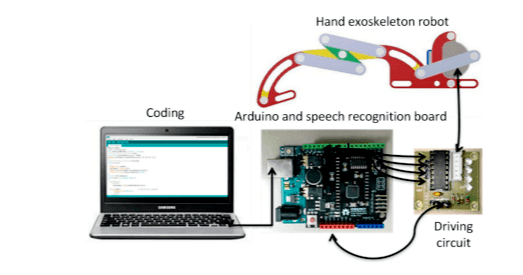

- Dissertation: Dynamic Assistant Finger Robot

- Published in the International journal: Inventions (ISSN: 2411-5134)

- Awarded Hiroshima exchange program scholarship

Projects

N5 Edge Particle reduction by the robot retrofit

1. Data collection and image analysis

2. Dismantling all the wafer transfer routes

3. Manual run wafer and stimulation to find any possibility

4. Tool robot retrofit from clamp-type to vacuum-type

5. Defect reduce 20% and increase production yield

Auto Swap Dummy wafer function

1. Project coordinator and scheduling arrangement

2. Production yield and wafer amount calculate

3. Co-work with IT teams and Manufacturing teams and Process teams

4. On-site testing and verification

Wafer thermal expansion improvement

1. Phenomenon observer and model analysis

2. Tool retrofit and transfer cycling testing

3. Data collection and critical dimension experience

4. Wafer Backside defect improvement by 10%

N3 Layer Particle reduction

1. Basic disassemble process

2. Analysis of film materials and inner interaction

3. Data and image collection and recording

4. Log analysis and find process weak point

5. Tool Parts correlation with Particle performance

6. Process sequence and recipe study and modify

The Study and retrofit of Water Heater with impulse Heat pipe

1. Equipment installment and design

2. Data collection and analysis

3. Heat pipe simulation and retrofit

4. Finding the weak point of the Water Heater

Dynamic Assisted Robotic Finger

1. Research on Sound Control and coding

2. Mechanism Design and material finger motion analysis

3. All system integration and reification

Contributions and reward

- Working PMD with twice Outstanding performance and Job grade upgrade to next level within 2.5 years

- Compiling twenty pieces of S.O.P files helps decrease the human error rate by at least 10%

- Awarded for Defect reduction and tool troubleshooting and recovery

- Development first specific tool Auto swap wafer function, increasing almost 15% production rate

- Analyzing abnormal phenomena with the FDC system and using this system promptly to prevent 100 pcs wafer scrap

- Responsible for special processes yield improvement project and increasing 5% yield rate

Skills

Language

- Excel

- AutoCAD

- SolidWorks

- ANSYS

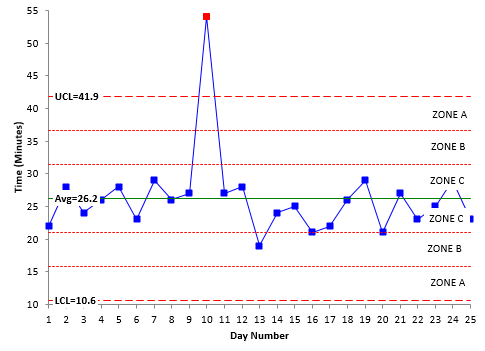

- SPC analysis

- FDC system

- Python

- Chinese — Native speaker

- English — Advanced (TOEIC:765)

- Japanese — Beginner