WU SHANG-RUEI, 吳尚叡

Hi, I'm Rex.

Keeping to be highly curious about everything is one of a belief in my life learned from my master's degree.

Live in Kaohsiung,TW

[email protected]/[email protected]

Quick View : Self-Introduction

Language

-English

Service experience in customer(US) support from Oct-2017 to Jun-2021

-Chinese (Mother tongue)

Education

Chung Yuan University

National Central University

Work Experience

Process Engineer ASE, INC. Jun 2016 ~ Oct 2017 (17 months)

Product/Process Integration Engineer ASE, INC. Oct 2017 ~ Present (28 months)

Skill

- Techniques Background

Ultra-high Vacuum Knowledge

Spectroscopy

- Engineering Graphics

Solid Work

- Data Analysis Software

Origin

Word/PowerPoint/Excel

Engineering Capability

- Process control and handling

- Process analysis techniques

- Process design practice and concepts

- Process quality management

- Process requirement management

My Hobby

- Swimming

- Working out

- Basketball

- Watching Drama

Work Experience

Product/Process Integration Engineer (產品暨製程整合工程師)

Advanced Semiconductor Engineering, INC. Oct 2017 ~ Jun 2021

- Advance module techniques development

- Publish a patent of 5G-SIP techniques.

SEMICONDUCTOR DEVICE PACKAGE AND METHOD OF MANUFACTURING THE SAME

US20200251449A1 published by 20200806

- New Product Introduction (NPI)

- Accomplish 3 kinds of the new product to the EVT stage and be qualified.

- Introduce one 5G-module product for mass production.

- Accomplish 3 kinds of the new product to the EVT stage and be qualified.

- Introduce one 5G-module product for mass production.

Laser Ablation Process Engineer (製程工程師)

Advanced Semiconductor Engineering, INC. Jan 2017 ~ Oct 2017

- New Process and Techniques Introduction

(Build up laser ablation related processes and techniques.)

- Transfer and develop laser ablation techniques from the flip-chip team to the module team.

- Establish process details in the module site.

- New Product Introduction (NPI)

- Successfully introduce 1 fingerprint product for mass production.

- Successfully introduce 1 fingerprint product for mass production.

Coating-Process Engineer (製程工程師)

Advanced Semiconductor Engineering, INC. Jun 2016 ~ Jan 2017

- Process Engineering fundamental skill learning

- Process control and handling

- Process analysis techniques

- Process design practice and concepts

- Process quality management

- Process requirement management

- New Product Introduction (NPI)

- Successfully introduce 1 fingerprint product for mass production.

Education

National Central University, Master's Degree of Physics, 2011 ~ 2014

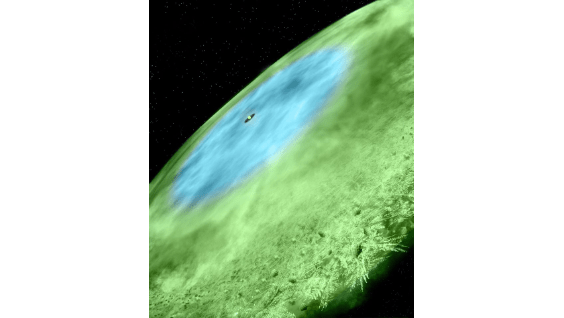

In the period of my master's degree, I study a topic of mimic outer space ice(interstellar ice ) in the lab. And All my ultra-high vacuum techniques and corresponding measurements were involved collected within this period.

- First of master's degree:

-Fundamental vacuum knowledge.

-Engineering graphics by SolidWorks.

-Vacuum system design capability enhancement by well training on the skill of lathe/milling machine.

-Manually practice or handling vacuum systems all the time.

- The second/third of master's degree:

-Supporting the researcher from INAF/NASA at NSRRC(National Synchrotron Radiation Research Center).

-CO2 interstellar ice photon-induced desorption research under thermal effect.

Chung Yuan Christian University, Bachelor Degree of Physics, 2007 ~ 2011

VUV Photon-Induced Desorption Of CO₂ Ice: Temperature Dependent Study

Abstract

Carbon dioxide (CO2) is one of the most abundant molecules present in interstellar ice after H2O and CO. In the high mass protostars, CO2 represents an important tracer of the chemical and physical history. Further, the photoprocess of CO2 ice has been being the main subject of experimental studies quite recently.

In this study, we present CO2 ice deposited and VUV irradiated at different temperatures (14 K, 50 K, 70 K), that aims to understand the thermal effect on the mechanism of photodesorption of CO2 ice. We used a microwave-discharge hydrogen-flow lamp to mimic the interstellar UV field (114−170 nm). A quartz crystal microbalance (QCM) and a fouier transform infrared spectroscopy (FTIR) were selected to be the principal instruments in two different experimental systems, and both systems equipped with a quadrupole mass spectrometer (QMS) to measure the desorbed species during the whole experimental process.

Mass spectra show that desorbed molecules mostly originated from the event, CO2 ice decomposed to CO. Secondary desorbed molecules come from the photolysis of CO2 ice as VUV irradiation proceeding to form O2. Finally, a few CO2 molecules directly desorbed from CO2 ice. According to our results, photodesorption yield increased with the increased accumulation of photolysis products, reached a limited value due to the photolysis product only can desorb the surface layers at the temperature below sublimation of CO (14 K). After the ice temperature was raised up to 50K and 70K, Photo-product CO will either desorbed from the surface and also from the deep layers of ice. The amorphous ice structure will turn into crystalline above 50K and beyond, so CO will struggle to migrate to the surface gradually. Until the crystalline structure of CO2 was fully destroyed, CO will sublimate freely within the ice interior.

Moreover, when CO2 ice was deposited and VUV irradiated at the temperature which is above the sublimation temperature of CO, we determined the maximum mobile distance of CO molecule in CO2 ice at 50 K and 70 K.

My thesis : https://hdl.handle.net/11296/xr3t3m