Mari K. Okami

Supply chain & operations professional, with a background in operations research & management systems. Over 14 years of management experience. Data-driven approach to process improvement and collaborative management style. Focus on value-driving strategies & implementations, and streamlining factory-to-consumer finished goods supply chains.

+1 917 767 6954

Lives in Salt Lake City, UT

14 years in New York, NY

Originally from Kamuela, HI

Areas of Expertise

Supply Chain & Ops

• Compliance

• Transportation Logistics

• Warehousing

• Fulfillment

• Purchasing

• Forecasting

• Inventory Management

Management

• Collaborative Team-Building

• Management by Objectives

• SOPs & Best Practices

• KPI Development & Capture

• Business Analytics

• Budgeting & Financial Forecasting

• Project Management

Technical

• Managing IT, integrations, automations, and new system implementations

• Leveraging miscellaneous web-based applications (Trello, Slack, Airtable, etc.) and other free or low-cost tools to add efficiencies wherever possible

Education

Columbia University, The Fu Foundation School of Engineering & Applied Science

Bachelor of Science, Operations Research: Engineering & Management Systems

Experience & Responsibilities

360 ELECTRICAL, LLC || Salt Lake City, UT

VP of Operations, 5/2021-Present

Director of Operations, 2/2018 - 5/2021

Direct Reports: Customer Service, Operations Coordinators, Purchasing Manager, Inventory & Fulfillment Manager, IT & Integrations Manager, Project Manager

- Report directly to the company President. Key member of the core leadership team within 360.

- Develop operational strategies in support of overall company growth, such as enhanced automation for order processing. Provide road maps for implementation, including budgetary needs/impacts, risk assessments, resource requirements, etc. Drive implementation process within the operations team and communicate progress out to company stakeholders regularly.

- Identify, engage, and contract third-party supply chain, logistics, and tech/systems partners as is appropriate to supplement our operational capacity and streamline our supply chain.

- Deploy continuous improvement and cost-saving processes for each Operations functional area to support productivity, morale, and growth.

- Provide ongoing support, career development opportunities, and personal growth opportunities for my direct reports. Act as an advocate for my team within the larger organization. Collaboratively set goals and provide the tools and resources to achieve success.

ALPHA DOMINCHE LTD. || Brooklyn, NY & Salt Lake City, UT

Director of Operations, 8/2015 - 1/2018

Direct Reports: Accountant, Lead Technician, Operations Coordinator, and Assembly Team (1 Assembly Team Lead & 3 Assemblers)

- Worked in conjunction with the CEO & CFO to develop organizational processes and accountability across departments.

- Direct

management and administration of all raw materials & components procurement

and purchasing, assembly, order fulfillment, inbound &

outbound freight, labor requirements,

tech support, and trade compliance.

- Researched and implemented cost-saving strategies across the supply chain to include a 17% reduction in small parcel & LTL freight costs; a reduction in assembly and inventory footprint of 50%, reducing rent costs; and scaled back assembly labor requirements by 25%.

- Implemented organizational structures & compliance with general standards. Sourced customs brokerage firm to ensure trade compliance on all inbound and outbound international shipments, including carnets, coffee & tea imports, machines and machine parts imports and exports.

BODUM USA, INC. || New York, NY

Operations Manager, 4/2013 - 8/2015

Supply Chain Manager, 6/2012 - 3/2013

Logistics Manager, 8/2010 - 5/2012

Direct Reports: Logistics Coordinator, Supply Chain Planner, Analyst, and Sales Coordinators (6)

- Developed, implemented, and optimized business processes. Translated strategic decisions into streamlined tactical processes.

- Managed factory-to-consumer supply chain and logistics, fulfillment, supply chain analytics, custom product development, and special projects for all revenue channels for the Americas.

- Created and refined analytical tools to support all business areas.

- Led monthly forecasting & budgeting activities and provided performance monitoring against budgeted goals and thresholds.

- Researched and implemented costsaving

strategies across the supply

chain, including inbound freight,

warehouse handling and storage, and

outbound freight.

BEEPOSH LLC || New York, NY & Rowayton, CT

Operations Manager, 9/2008 - 6/2010

Direct Reports: Customer Service Manager, Billing Administrator, Order Entry Clerk, Operations Coordinator

- Managed operations department, including customer service, order fulfillment, logistics, and compliance. Reported directly to the company President.

- Acted as the primary liaison with third-party warehouse for shipping scheduling and inventory management. Coordinated order processing with production schedules and inventory levels.

- Implemented and managed EDI and drop-ship programs with key accounts through integration with semi-proprietary ERP and third-party applications. Set up supplier compliance practices and procedures for all new major accounts, including Macy’s, Amazon, Dillard’s, Toys’R’Us, and FAO Schwarz.

- Successfully transitioned warehouses and fulfillment operations accordingly. Negotiated payback of vendor chargebacks with 3P warehouse.

REYN SPOONER & REYN'S MENS WEAR || Kamuela, HI

Credit Manager, 9/2006 - 7/2007

- Maintained all accounts receivable and performed collection activities for non-factored accounts. Reported to the Chief Financial Officer.

- Worked with a factor to process charge-backs and resolve payment conflicts.

- Reviewed all customer orders for approval based upon credit line and account status.

- Performed month-end reconciliations and generated reports for all receivables.

360 ELECTRICAL

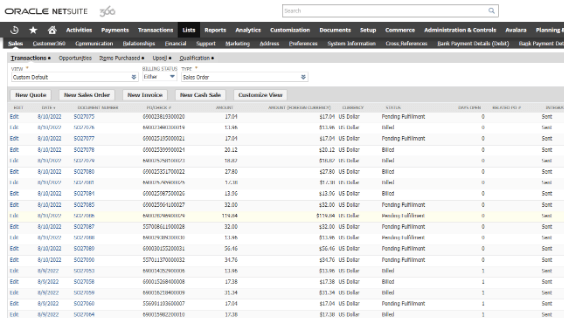

Refined the implementation of the Netsuite ERP, and further implemented the Demand Planning, Planning & Budgeting, and Manufacturing & Assembly modules. Oversaw the integration of Netsuite with Shopify via the Boomi platform, and integrated over 90% of our active customers with EDI automation, including automating documents between Netsuite and our warehouse's WMS. Created the digital infrastructure for new revenue channels, i.e., drop ship. Automated transaction processing wherever practical and feasible in Netsuite.

Continuously pursued and implemented various cost-saving initiatives and other value-add measures across the supply chain. Reworked our small parcel agreements to achieve a 37% cost reduction. Responded to rapidly changing market conditions on TPEB lanes to ensure best available transit times during peak demand. Negotiated a 7% cost reduction on outbound LTL/FTL deliveries during a period of low equipment availability & increasing FSCs. Transitioned to a new warehouse and achieved over 30% cost savings on warehousing and fulfillment.

Brought 360 Electrical from the brink of potentially losing our bank relationship in 2018 through rapid and vigorous inventory management overhaul. Identified, vetted, and moved to a new warehouse within 3 months of determining poor management and limited capabilities with existing warehouse. Implemented ABC cycle counting after full physical inventories and reconciliations. Hired an outstanding inventory manager to carry forward and continue to improve upon the strides made in cleaning up our inventory management processes.

ALPHA DOMINCHE

Implemented cost-saving strategies across the supply chain to include a 17% reduction in small parcel & LTL freight costs; a reduction in assembly and inventory footprint of 50%, thereby reducing rent costs; and scaling back assembly labor requirements by 25% through better monitoring of productivity and output levels.

Implemented structure & compliance with general industry standards throughout the organization. Sourced customs brokerage firm to ensure trade compliance on all inbound and outbound international shipments, including securing carnets, exports and imports of coffee & tea, and exports and imports of machines & machine parts.

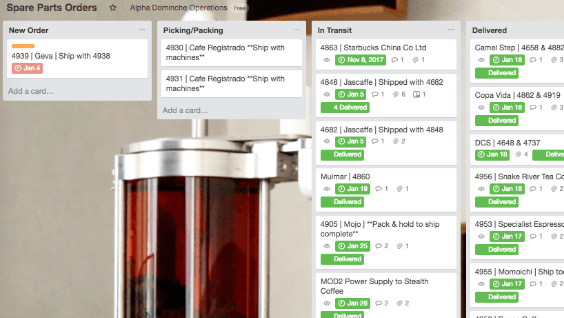

Digitized most administrative operations through implementation of Slack and Trello to remove paper from daily workflows. Set up customized integrations between both programs to reduce unnecessary follow up and communication distractions during the work day, and facilitate long-distance management of assembly operations.

BODUM

Managed entire Starbucks relationship, a $6M annual revenue business, including all Starbucks, Teavana, Tazo, and Seattle's Best customized and branded products, as well as factory SSR compliance and remediation. Met directly with Howard Schultz during business trips to the Starbucks HQ in Seattle.

Managed the production and delivery of over a million units of inventory across two brands to over 1000 “shop-in-shop” JCPenney locations. Simultaneously implemented RFID technology throughout the Bodum supply chain in compliance with JCP’s vendor requirements at the time.

Initiated trade compliance projects including complete HTS code review for import into the US and Canada, Canadian duty drawback program, and protest filings for 2013 entries. Filed amendments resulting in $46K in recoveries from the CBSA.

Sourced and transitioned to a new domestic warehouse to manage inventory and fulfillment operations for the Americas. Implemented RF scanning, FIFO, and lot tracing processes to improve inventory accuracy and align our operations with industry standards. Achieved 17% overall reduction in warehousing costs. Changes proved crucial in managing the reverse logistics of over 1 million units of recalled product from all Starbucks stores in 2015.

Avid gardener and home cook. Interested in foraging, food preservation, and self-sufficiency. Amateur beekeeper and chicken mom. Love to backpack and immerse myself in nature during my free time. Trying to control my travel tooth. Occasionally dabble on the piano.