— Ray Cho(卓緯翰)

Contributing for a better world by service for 4+ years experience as a customer service engineer. Participate in several core projects and modifications collaboratively and support relocation projects.

- E-mail: [email protected]

- Phone: 0958918874

Education

Feng Chia University 2006 - 2010

Department of Aerospace and Systems Engineering

Experience

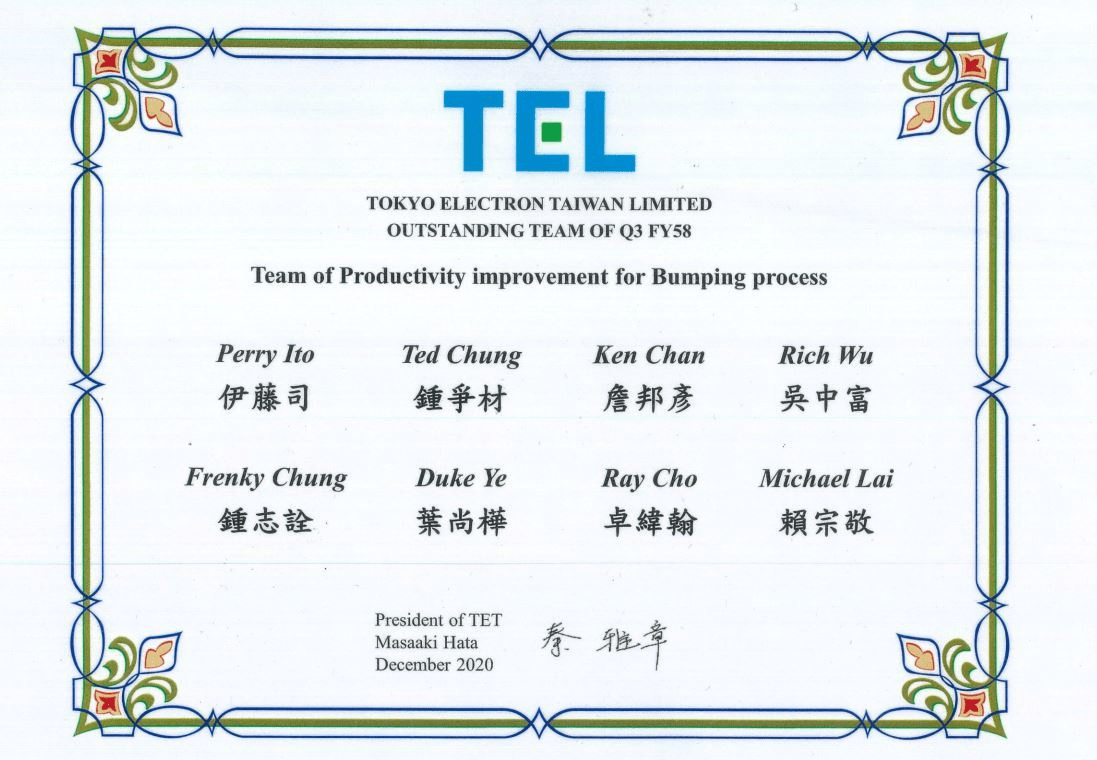

Customer Service Engineer Tokyo Electron Limited, Taiwan Branch--2020.4 - Present

2020.11 to now Service in TSMC F18

Completed hardware modification including transfer arm, process unit, chemical piping, the electrical, software upgrade for next-generation product.

Analyze the root cause of equipment or process issues and offer solutions to customers.

Coordinate action plans with customers and assigns the job to subcontract engineer.

2020.4 to 2020.11 Improvement for MTB bumping process

The new design cover improves the thickness problem during oven baking and it's successfully promoted and extend the new cover design to other factories, which can reduce cost by about NTD 5,000,000.

Customer Service Engineer Hermes Epitek Limited, Taiwan--2016.10 - 2020.4

2018.5 to 2020.4 Service in Linko

Transferring to Linko customer service team to serve MTTW, NTC3, TSMC AP3, and ASECL. Different customers, machine types,s, and processes make me understand more about the evolution and construction of each generation of machines.

2016.10 to 2018.4 Service in TSMC Fab12

Since TSMC Fab12 is RD fab, customer improvement proposals are provided through experimental data for hardware modification, parameter optimization, and troubleshooting.

2018 to 2019 MTTW Bypass module recovery project

The goal is to reduce the bypass rate by 90% to 20% within 6 months of improving customer production capability.

Skills

- Word

- PowerPoint

- Excel

Languages

- English

- Chinese

Projects

Improvement for bumping process

Through this improvement project, the quality of customers' products has been improved and productivity has also been increased by 30% in total.

Bypass module recovery

Reducing the bypass rate by 90% to 20% within 6 months and bringing over 10 million profit to our company.