Roby Syuhada

Mining / Mine Plan Engineer

(+62)81222829625

Biola No. 8 Bandung, Jawa Barat, ID

[email protected]

Skill & Achievement

Mining

- Supervised 900k tpm delivery and coal quality assessed front to barge.

- Managed fleet match 25-PC2000 & 3-EX3500 with 140-HD785.

- Improved Pit-CPP haul cap. (22k to 25k tpd) with 6-Double Trailer Trial.

- Reduced 48-HD785+HD777 FBR (save 7% fuel) by ECO-Mode optimization.

Mine Plan

- Orchestrated nickel wet ore blending prod. (RKEF, Heap Leach, and HPAL) to optimize additional 2 million reserve.

- Implemented:

- Open pit coal avg. SR 5:1 within 14Ha with crest-toe level 45m (LOM 4yr)

- Open-cast nickel avg. SR 1.64:1 and COG Ni 1.6% within 1.24k Ha with crest- toe level 85m (LOM 12yr)

General Mgt. Ops.

- Reduced 2018 Q1-Q2 Incident Rate 11% by implementing Safety Accountability Program (SAP)

- Facilitated EHS Automation System Upgrade (RFID) with Auto Tracking + Clustering Data

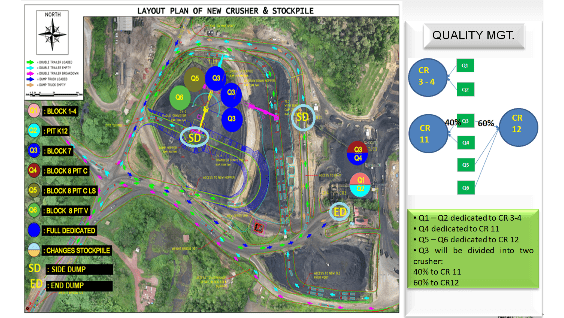

- Implemented Radial Crusher Design Construction (CR-12) for coal blending variance (5-6 types)

- Reduced 3s of barge mooring time by implementing dredge operation.

Exploration

- Led 1 unit Jackro 175 drilling ops. in 2 months resulting 800k ton coal resources with GAR 3300-3500 (Balikpapan formation).

- Led 2 unit Jackro 175 drilling ops. in 3 weeks resulting 150k ton coal resources with GAR 4400-4900 (Pulaubalang formation).

Software & Device

- Mining Design (Vulcan 8, Surpac 6.4.1, Datamine Studio 3, Minex 6.3, Minescape 5.7)

- Mapping & Geotechnical (GPS, Surfer 13, Global Mapper, Slide, Rocfall)

- Data Analytics & Presentation (Excel Pivot + Visual Basic, PPT Thinkcell, Project Gantt Chart, Visio Flowchart)

- Drafting & Design (CAD Civil 3D, SketchUp)

- Video (AdPremiere + DJI Phantom 4)

Marketing & Language

- Obtained off-takers agreement with coal trader/buyer (Glencore, Far East, Nobel, and HMS Bergbau Indonesia).

- Obtained a discounted fee sample analysis (10%) with Geoservices Lab.

- Obtained a discounted price (10%) and 2-stage term of payment instead of full payment in advance with Coates Service & Valfrol Dewatering.

- Advanced proficient in English Business Conversation (iBT 87), native in Bahasa

Projects

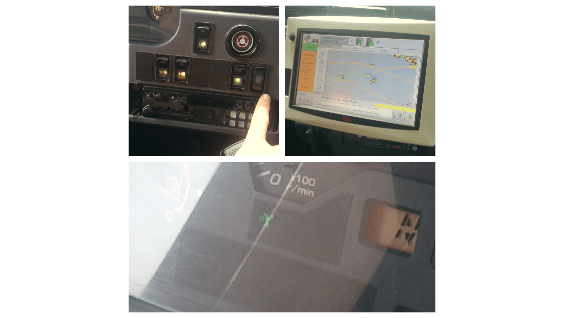

Spearheaded ECO Mode research by experiencing it directly on operator cabin (HD785 / CAT 777) by:

1. Utilize ECO Mode, evaluate Modular data bank, and optimize ECO Mode (Komatsu/CAT)

2. Fuel Efficiency results: 7-11% lesser FBR (lt/hr) with minimum usage 60% ECO Mode.

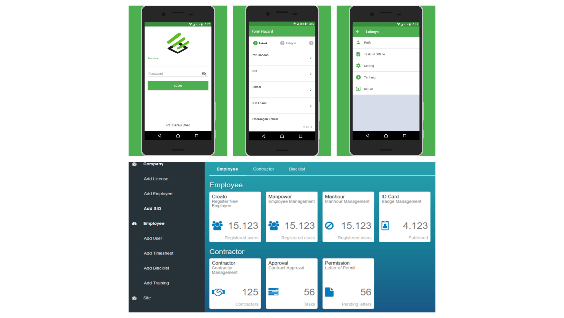

Facilitated EHS and Compliance System Upgrade by:

1. Integrating technology RFID, cloud database, and on-site personnel activity (inspection-investigation etc.)

2. EHS Automation results: Comprehensive Site-to-HQ Live EHS Data for deep analytical of preventive incident presented with interactive (custom design).

Generated opportunity of new marketing products with:

1. Implementing Radial Stacker Crusher Design (CR-12) to prepare 5-6 coal qualities blending

2. Total project value approx. $3million.

Work Experience

PT. Sulawesi Cahaya Mineral, Mine Planning Engineer

Dec 2018 ~ Present

PT Indo Mining Services, Mining Project Manager

Jun 2018 ~ Dec 2018

PT Berau Coal, Mining Engineering and General Management Operation Jul 2016 ~ Jun 2018

PT Rokatera Prima Minera, Mining Geology and Planning Engineer

Oct 2014 ~ Jul 2016

PT LAPI ITB, Mining Environment Researcher

Oct 2013 ~ Oct 2014

Education

Institut Teknologi Bandung, Master of Science (MS), Mining Engineering & Mine Environmental Management, 2013 ~ 2014

Institut Teknologi Bandung, Bachelor of Science (BS), Mining Engineering & Mining & Oil Exploration, 2009 ~ 2013