Sean Chang

I graduated from Feng Chia University, where I majored in Department of Industrial Engineering and Systems Management then started my career at Rich Shine International Co., Ltd.

I've served six brands, developed hundreds of models and over one million pairs are produced. These products have brought more than US$20 million of revenue since 2014.

EDUCATION

B.B.A., Industrial Engineering and Systems Management, 2013

Feng Chia University, Taichung, Taiwan

WORK EXPERIENCES & RESPONSIBILITIES

Rich Shine International Co., Ltd.

Product Development • B2B Business November 2014 - April 2019

◎ Contact customers for product research and development, offer advises and assistance

◎ Translate and compile designers' tech pack / drawings

◎ Source and collect materials to develop new products

◎ Organize the materials and create BOMs

◎ Lead the team and staff, explain the ideas and requirements from clients

◎ Set up the timeline to arrange every processes

◎ Follow up the schedule to make sure the product will be ready on time

◎ Inspect the processes on production line to control the quality and outcome

◎ Calculate the material usage

◎ Cost finding, provide product cost to customer

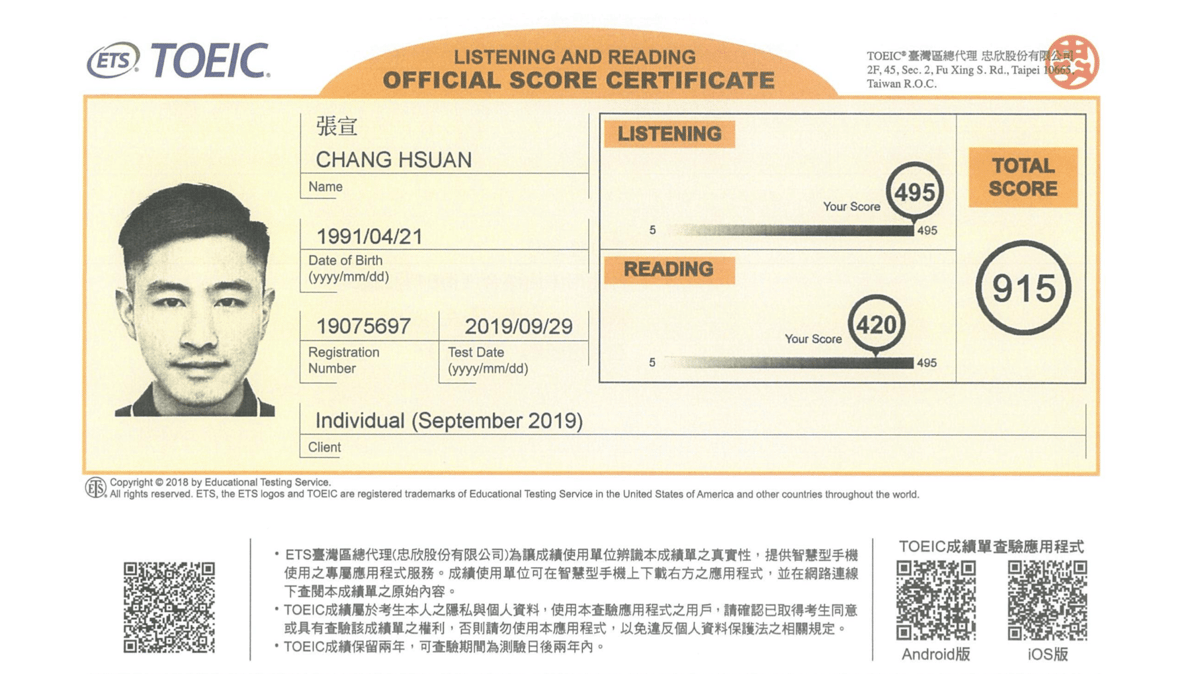

TOEIC Score: 915

My name is Sean Chang, graduated from Feng Chia University, where I majored in Department of Industrial Engineering and Systems Management. I am keen on shoes and sneakers, so I started my career at Rich Shine International Co., Ltd., a shoe factory based in Dongguan, China after honorably discharged from military.

By working for this company and visiting various kinds of vendors over the years, I established different types of knowledge. These experiences became the cornerstone of my abilities on material sourcing, management, research and development. As my experience increases, I have the capability to organize the works from customer, factory to supplier and serve as a product development manager.

Since 2014, I've served six brands, developed hundreds of models and produced over one million pairs. These products brought more than USD 20 million of revenue.

I mainly work with clients from America, Hong Kong, China, etc., to analyze their concepts and prospects. Most importantly, I give them suggestions to make the ideas become realities, attain the possibility for mass production and make the products more competitive. Once every two to three months, the development/design teams of different brands will come to our factory from the U.S. to discuss the projects for new seasons. I also bring them to the suppliers to present the new techniques and apply them to further merchandises.

Our team also visits the customers in the U.S. every six months or every year to work with them without time difference. We attend their sales meeting with all of the members, including executives, staffs and also the dealers from different countries. This let us receive the feedback that closet to the market and digest these comments to different departments of our factory. We can improve our policies by the information to meet customers’ expectations.

In the factory, I compile the designs and ideas from the clients then simplify them into images or specs to let the staff understand what the customers need and lead them to achieve the goals. The whole process includes material sourcing, supplier connecting, scheduling, process inspecting, BOM creating, material usage calculating, cost finding as well as helping the transfer of technology from sample to production.

As a product manager, I suppose it’s important to take yourself as a consumer, then you can equipoise “customer’s ideal” and “manufacture’s reality”, make the production achieves the highest benefits.

CUSTOMERS

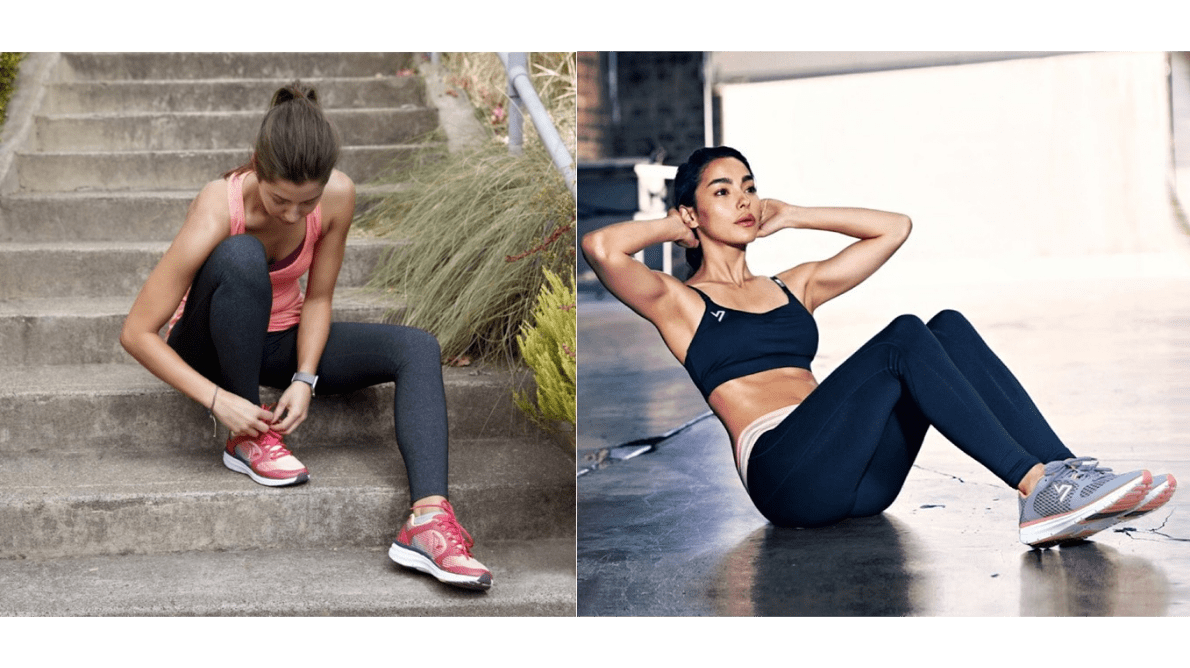

VIONIC

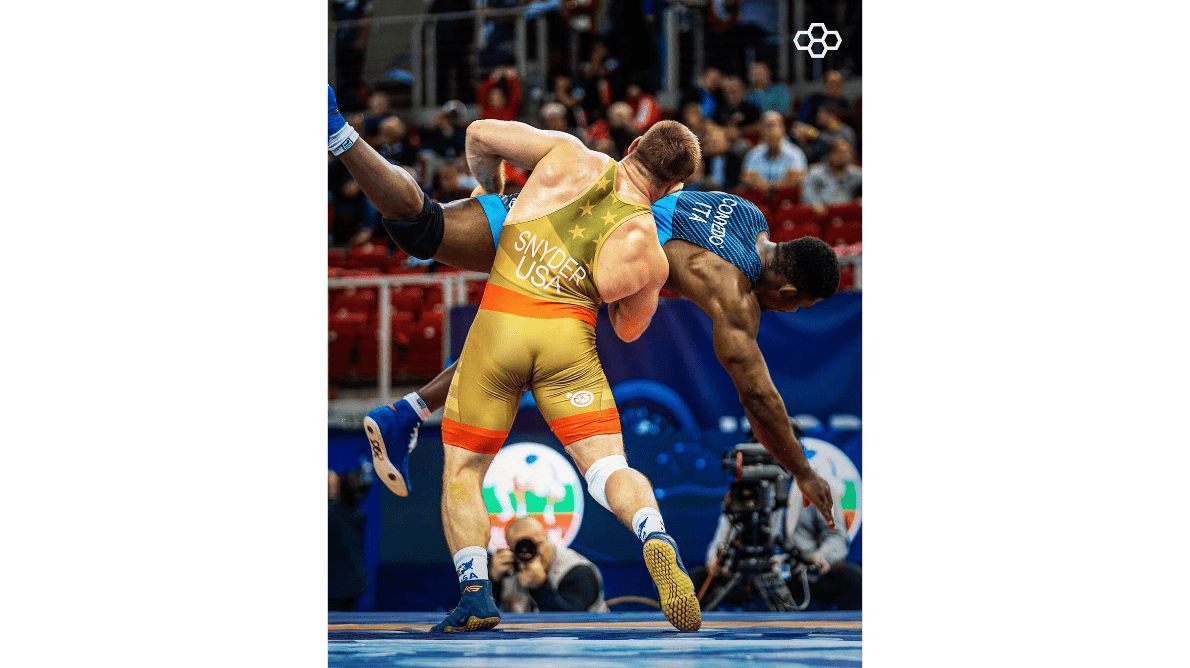

RUDIS

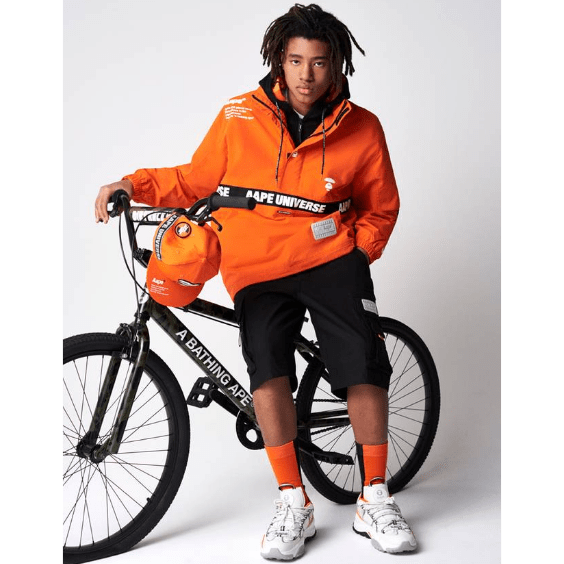

AAPE BY A BATHING APE

NBALAB

● A casual-wear brand of NBA

● They began the footwear business since 2017 and developed two different models for 14 most popular teams, there are more than 20,000 pairs put into production

UMBRO

AETREX

ORTHOTIC SHOES

WRESTLING SHOES

ACTIVE & CASUAL SNEAKERS

Aape launched three models in SS19, two of them are active sneakers that featured by engineered knit uppers and IP midsoles, embellished with pop-out printings, silica gel printings and embroideries.

The third style is “Chunky Shoe”, a casual sneaker that featured by complicated materials, workmanship and heavy-looking outsole, which are the most popular elements in fashion.

FOOTBALL CLEATS